AH Automation provides 100% DPM read-rate for Volvo Cars

Volvo Car Corporation in Skovde turned AH Automation with a request for a vision systems for reading DPM – Direct Part Marking on their engine blocks.

Our competitors said it is not possible to meet the Volvo Cars requirements.

“We proved the contrary by clever design, hard work and using the latest Scorpion Compact Vision innovations from Tordivel” says Jimmy Kleibrant Chief Vision Officer at AH Automation.

Datasheet from AH Automation in Swedish – RIA25 Referensblad Volvo

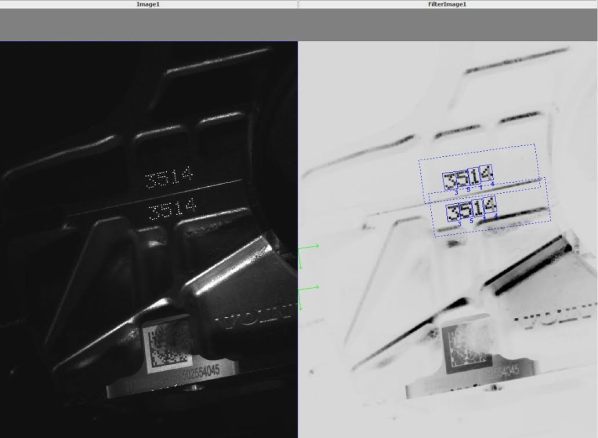

The easy part – Good Part Marking

Thor Vollset – CEO Tordivel AS says:

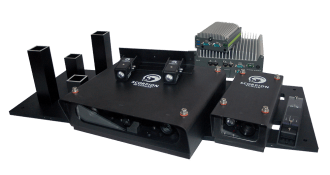

“We are so excited with Scorpion Compact Vision and how AH Automation turns it into a unique solution for Volvo Cars – they say it is 100% and we believe them. The Stinger products are design to run 24-7 in the most demanding applications. The Scorpion Stinger hardware is of course powered by the latest version XI of the proven Scorpion Vision Software framework”

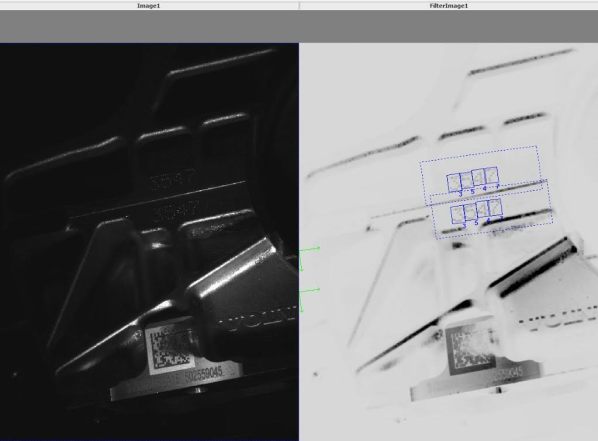

The not so easy part – Bad Part Marking

The bad parts is also read 100% by the optimised hw and sw component chain:

- Scorpion 2D Stinger Camera

- Sony XCG-99E camera with high quality CCD sensor

- Scorpion Stinger LEDspot – easy to mount and powerful led strobe

- Directly controlled by the Scorpion 2D Stinger Camera

- The latest Scorpion Vision Software version XI

- Including the proven TemplateFinder3 used for DPM

- Advanced Image Filtering techniques

Scorpion Compact Vision Concept

Scorpion Compact Vision System provides powerful machine vision for 2D and 3D applications without the need of programming skills. The Scorpion Stinger family of hardware components are compatible with Scorpion Vision Software. We provide all hw and sw components needed to make machine vision automation. This includes configurable sw for 2D and 3D image processing, image storing and traceability, data logging, configurable IO, interfacing with PLCs, robots and databases, support for the latest GigE cameras with cost and quality tailored to the application. In the Scorpion Stinger family there are industrial IP-64 2D and 3D cameras with integrated illumination, industrial LEDbars and support for a large number of flexible IO modules. The Scorpion Vision Software supports more or less any protocol like rs-232, tcp/ip, modbus, profibus and OPC.

Scorpion Compact Vision solves almost any tasks within 2D and 3D robot vision, label inspection, assembly verification, colour identification and gauging.

You must be logged in to post a comment.